-

Product DescriptionCompany Info.<>

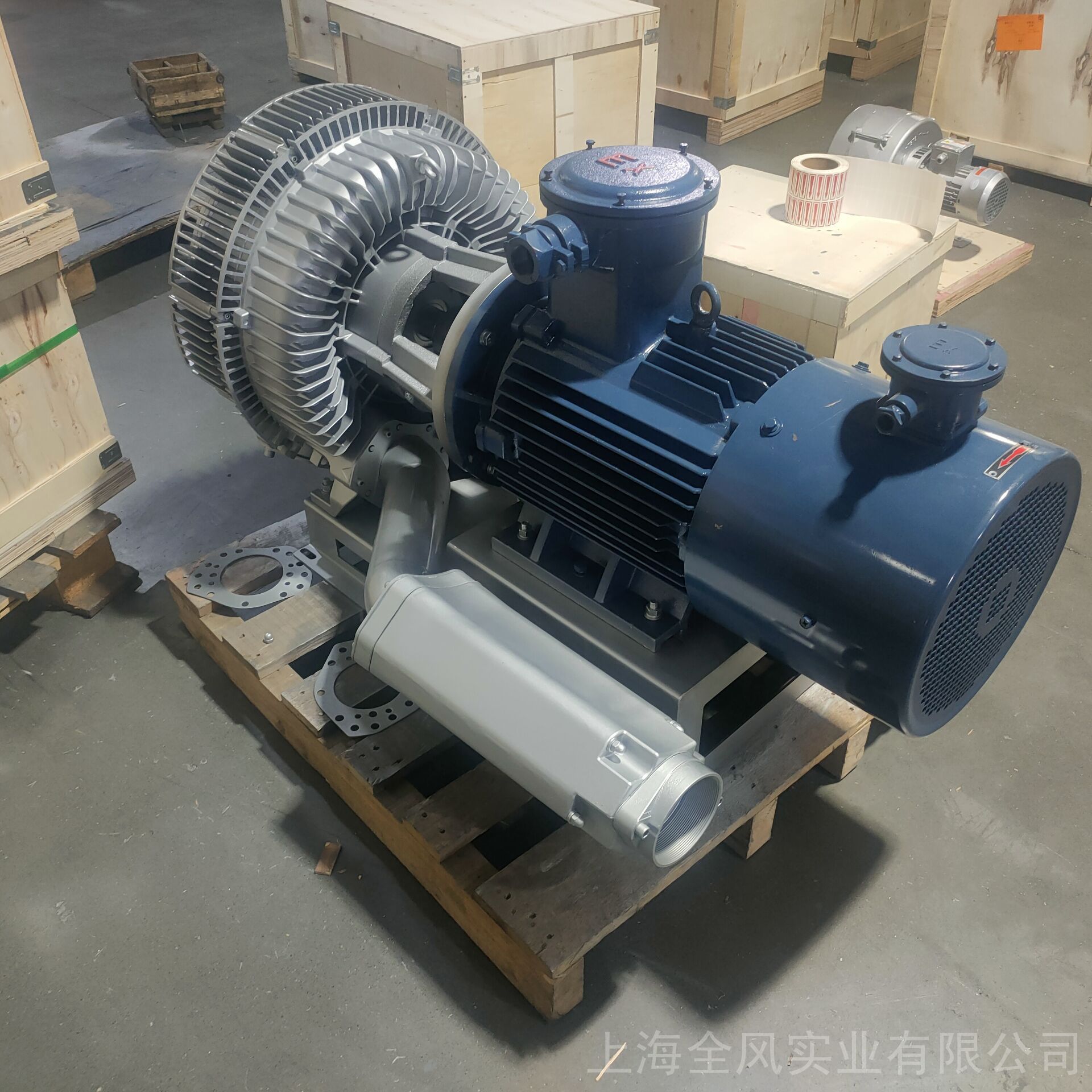

- Model:

- full wind

- Material:

- aluminum alloy

- Shaft power:

- 18.5 kw

- Weight:

- 220 kg

- Rotational speed:

- 2900

- Matching motor power:

- 18.5 kw

- Applicable scope:

- Explosion-proof fan, explosion-proof blower, dust explosion-proof

Introduction:

Dust explosion-proof fan is under normal operating conditions will not produce arcs, sparks or dangerous high temperature motor structure, and then take some mechanical, electrical and thermal protection measures to further avoid normal or approved overload conditions arc, spark or high temperature hazards, thereby ensuring its explosion-proof safety.

Details:

* Harmful gas explosion-proof fan *

Our company adheres to“ the business philosophy of honesty, integrity, quality and customer-oriented”. We practice“ the service tenet of answering questions, answering results, re-righteousness and trustworthiness, and doing” our best. All products have a 12-month warranty period. We are willing to serve new and old customers wholeheartedly!

Dust explosion-proof fan overview

The fan uses a flameproof enclosure to isolate electrical components that can generate sparks, arcing and dangerous temperatures from the surrounding explosive gas mixture. However, the enclosure is not hermetically sealed, and explosive gas mixtures from the surroundings can enter the interior of the motor through the gaps between the joint surfaces of the various parts of the enclosure. Explosion may occur when it comes into contact with ignition sources such as sparks, arcs, and dangerous high temperatures in the enclosure. At this time, the flameproof enclosure of the fan will not be damaged or deformed, and the explosive flame or hot gas will not ignite the surrounding explosive gas mixture when it is transmitted through the gap between the joint surfaces. 1, explosion-proof performance in line with the new national electrical safety standards: explosion-proof performance in line with GB3836.1 - 2010 "electrical equipment for explosive gas atmospheres Part 1 General requirements" and GB3836.2 - 2010 "electrical equipment for explosive gas atmospheres Part 2 Explosion type d" provisions, also in line with IEC 60079 - 1 and European standards. 2, high explosion-proof, reliable operation: motor protection pole IP55, shaft penetration position using V-type shaft seal ring, junction box using circular stop plus seal ring, improve the processing accuracy of main parts, base using parallel vertical fin structure, increase the heat dissipation area and other electrical and mechanical design measures, in terms of dust and water to improve an equal pole, motor operation more reliable.

Dust explosion-proof fanis under normal operating conditions will not produce arcs, sparks or dangerous high temperature motor structure, and then take some mechanical, electrical and thermal protection measures to further avoid normal or approved overload conditions arc, spark or high temperature hazards, thereby ensuring its explosion-proof safety.

Dust collection explosion-proof high pressure, medium pressure fan specifications

Power :0.18KW, 0.4KW, 0.75KW, 1.5KW, 2.2KW, 3KW, 4KW, 5.5KW, 7.5KW, 11KW, 15KW, 18.5KW, 20KW, 22KW, 25KW, 30KW, 37KW;Wind pressure:50mbar-650mbar;Air volume:40 cubic/hour-1134 cubic/hour, for the convenience of different specifications, single/double stage are available;Frequency:50Hz, 60Hz;Voltage:110V-615V, all countries can use. If special voltage is required, it can be customized according to requirements.

Working principle of dust collection explosion-proof high-pressure fan

After the power supply is turned on, the fan rotates. Because the impeller has a groove design, it will drive the air flow, so the air enters the pump body through the air inlet, and the air is stirred inside. Each groove is pressurized by vortex type, and a cycle of pressurization is formed to form powerful airflow energy. It is discharged from the pump body through the air outlet for use.

Dust collection explosion-proof high-pressure fan structure

1 . Impeller: involute profile is selected, and the volume utilization rate is high. 2. Bearing: Type 3000 double row radial spherical roller bearing is used as the positioning end near the coupling end. 32000 type single row radial short cylindrical roller bearing is selected as free end near gear end to adapt to axial displacement of rotor during thermal expansion. 3, the body: by the shell and left and right wallboard composition. The left and right wall plates and bearing seats and sealing parts installed in the left and right wall plates can be mutually used. 4, base: medium and small fans are equipped with a common base, large fans only equipped with fan base, easy to install and debug. 5. Transmission mode: mainly coupling direct connection. If the performance specifications require, you can also choose the V-belt pulley speed change mode. Coupling selection of flexible coupling, can ease the impact and compensate for a small amount of axis deviation. In addition to electric motors as drive motors, steam turbines or other drive motors can also be used for large flow fans. nbsp;

Dust collection explosion-proof high-pressure fan configuration

1 . Case material: super strength die-casting aluminum, die-casting aluminum is the same as Mercedes-Benz car wheel aluminum, compared with ordinary aluminum alloy, die-casting aluminum is stronger, compared with iron shell fan, more lightweight effect. 2, motor performance: the use of broadband, wide voltage motor, included in single-phase 110V, 230V; industrial three-phase 220V, 380V, 415V, 660V, etc., motor frequency can be 45-75HZ frequency modulation, IP55 protection level F insulation level, its advantage is that the domestic motor can not reach the process, favored by domestic and foreign customers. 3, fan oil seal: fan using high-quality brand oil seal and high-quality brand fluorine rubber can withstand-25℃ to 300℃. Compared with the general oil seal, the lip temperature is 20~50℃ higher than the working medium temperature, the performance is more stable, maintenance-free, and the service life is longer. 4, fan bearings: the core parts of the fan using German SKF, Japanese NSK brand bearings, bearingscan withstand350 degrees Celsius, 4000 rpm speed, stable performance, low noise, maintenance-free, longer life, can ensure that the fan runs longer.

Dust collection explosion-proof high-pressure fan function

It is an explosion-proof fan product with explosion-proof performance in line with relevant electrical standards; it is a motor structure that does not produce arcs, sparks or dangerous high temperatures under normal operating conditions, and then takes some mechanical, electrical and thermal protection measures to further avoid the danger of arcs, sparks or high temperatures under normal or approved overload conditions, thus ensuring its explosion-proof safety. Mainly used in coal mine, petroleum and natural gas, petrochemical and chemical industries. In addition, it is widely used in textile, metallurgy, city gas, transportation, grain and oil processing, papermaking, medicine and other departments. Explosion-proof motor as the main power equipment, usually used to drive pumps, fans, compressors and other transmission machinery.

Dust collection explosion-proof high-pressure fan characteristics

1 , with blowing and suction dual functions, one machine dual-use, can use suction, can also use blowing;2, less oil or oil-free operation, the output air is clean;3, relative to centrifugal fans and medium pressure fans, its pressure is much higher, often more than ten times that of centrifugal fans; 4, if the pump body is a whole die-casting, and the use of anti-vibration mounting feet, then it is also very low requirements for the installation of the foundation, even can not be fixed feet can operate normally, very convenient, but also very save installation costs and installation cycle;5, relative to similar fans, its operation noise is low, such as our company launched ultra-quiet vortex fan;6, maintenance-free use; its loss is only two bearings, in the warranty period, basically no maintenance; 7, the mechanical wear of the vortex blower is very small, because in addition to the bearing, there is no other mechanical contact part, so the service life is of course very long, as long as it is in normal use conditions, 3 to 5 years is completely no problem;8, easy to install, easy to use;9, the overall use of aluminum alloy material, the motor is explosion-proof motor, there will be no friction spark phenomenon, use more assured, explosion-proof performance is better.

Dust collection explosion-proof high pressure fan performance advantages

1 , ultra-quiet type, no noise: the motor runs directly, and by adding an integrated sound suppression facility, the phenomenon of high pressure fan noise is improved, so as to achieve the effect of silence. 2, high reliability When the use of changes, the machine can still operate safely. In addition to the impeller, the high-pressure blower has no other action, so the reliability is almost maintenance-free. Using precision outer bearings with good heat dissipation, it has the following advantages: high compression ratio; low bearing operating temperature; long grease life; maintenance-free. 3, easy to install fully equipped, can be installed and used at any time, for compressed air or for vacuum, can also be installed in the horizontal or vertical direction. 4, oil-free pollution-free impeller rotation, not in contact with any part, free of lubrication, so can ensure pollution-free. 5, after many years of manufacturing experience, precision mechanical design plus careful motor with standard instrument testing, the use of all parts can meet the requirements, the use of standard ip54, F class motor efficiency, very few failures, between the motor and blower shaft seal test, to prevent foreign matter from entering. At the same time, in order to ensure the functional effect, each blower is strictly tested before leaving the factory. 6, voltage: international voltage type, 50HZ 60HZ are available, whether your product is exported to Europe and the United States using 60Hz, high voltage countries, or the Middle East, Africa and other countries and regions using 50Hz voltage, fans can meet the requirements, functional production complete, so that you have no worries!

Dust collection explosion-proof high-pressure fan range of use- Machining manufacturing industry: cleaning all kinds of metal chips and dust, especially cast iron processing shows its superiority. 2, glass fiber manufacturing industry: absorption of glass fiber products in the manufacture of hardened surface grinding dust and residue. 3. Biopharmaceutical industry: dust removal and purification for production workshops. 4, food industry: absorb oil smoke, moisture and food residues. 5. Food items: used for large-scale grain handling, transportation, storage and cleaning. 6, chemical plants: welding dust, welding smoke, powder, granular harmful substances absorption. 7, thermal power plant: used to clean up the deposition of dust, slag, especially for the daily cleaning of boilers, regular maintenance of ash removal. 8, microelectronics industry: for the production workshop dust removal, purification and shear waste recovery. 9, battery manufacturing industry: used for production workshop cleaning and waste recycling.

High-pressure fans for conveying high-temperature gases can be installed at any time in the place of use for compressed air or for evacuation. And can be installed arbitrarily horizontal or vertical direction. 1. It is necessary to use flat washers and spring washers to tighten screws;2. Rubber buffer rubber can be used to withstand the weight of high temperature gas high pressure fans, especially high power high temperature gas high pressure fans;*;3. For some noise requirements, it can be installed to reduce noise.(In general, about 5dB), installed at the end of the air inlet pipe or air outlet pipe;4, for some occasions with high noise requirements, according to the conditions of the machine itself, plus a layer of muffler, you can meet the noise requirements of the site, specifically consult the manufacturer or noise control company of the high-pressure fan that transports high temperature gas; 5. When using muffler, pay attention to the distance between the fan and the box, pay attention to the ventilation and heat dissipation of the fan, pay attention to the use of rubber buffer to bear the weight of the high temperature gas high pressure fan, and specifically consult the manufacturer of the high temperature gas high pressure fan;6. The air inlet and outlet pipe connection of the high temperature gas high pressure fan should be connected with hose to isolate vibration; 7, the application of Ramallah out, while not missing the adjustment gasket, so as not to affect the factory has been adjusted good clearance;8, it is strictly prohibited to solid, liquid and corrosive gas into the pump body;9, the inlet and outlet of both ends of the filter and should be timely cleaned according to the situation, so as not to block the impact of use;10, the inlet and outlet connection must be hose connection (such as rubber pipe, plastic spring pipe).

- Name(chinese)

- Name(English)

- Shanghai Quanfeng Industrial Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Shanghai, China

- Nearby port

- Suzhou,Nanjing,Zhenjiang,Lianyungang,Shanghai

Shanghai Quanfeng Industrial Co., Ltd. is a company specializing in the production of transmission equipment. The company mainly specializes in Taiwan's full-wind high-pressure blowers, through-pressure blowers, low-pressure blowers and vacuum cleaners environmental protection equipment products. Through several years of development, Quanfeng Company has established a complete personnel system from sales, technology to after-sales service, and adheres to the business goal of sustainable operation, and strives to become the best environmental transmission supplier in the industry. Main products: all-wind fans, all-wind blowers, all-wind ring blowers, all-wind high-pressure blowers, all-wind through-flow blowers, all-wind insulation blowers, all-wind multi-blade blowers, all-wind through-flow multi-stage blowers, all-wind explosion-proof high-pressure blowers. Wait.- Name(chinese)

- Name(English)

- Shanghai Quanfeng Industrial Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Shanghai, China

- Nearby port

- Suzhou,Nanjing,Zhenjiang,Lianyungang,Shanghai

Shanghai Quanfeng Industrial Co., Ltd. is a company specializing in the production of transmission equipment. The company mainly specializes in Taiwan's full-wind high-pressure blowers, through-pressure blowers, low-pressure blowers and vacuum cleaners environmental protection equipment products. Through several years of development, Quanfeng Company has established a complete personnel system from sales, technology to after-sales service, and adheres to the business goal of sustainable operation, and strives to become the best environmental transmission supplier in the industry. Main products: all-wind fans, all-wind blowers, all-wind ring blowers, all-wind high-pressure blowers, all-wind through-flow blowers, all-wind insulation blowers, all-wind multi-blade blowers, all-wind through-flow multi-stage blowers, all-wind explosion-proof high-pressure blowers. Wait. -

Send your message to this supplier*From:*To:

Mr. zhu

*Message:

Mr. zhu

*Message:Inquiry

Copyright © 2003 - 2026 Goepe.com All rights reserved.